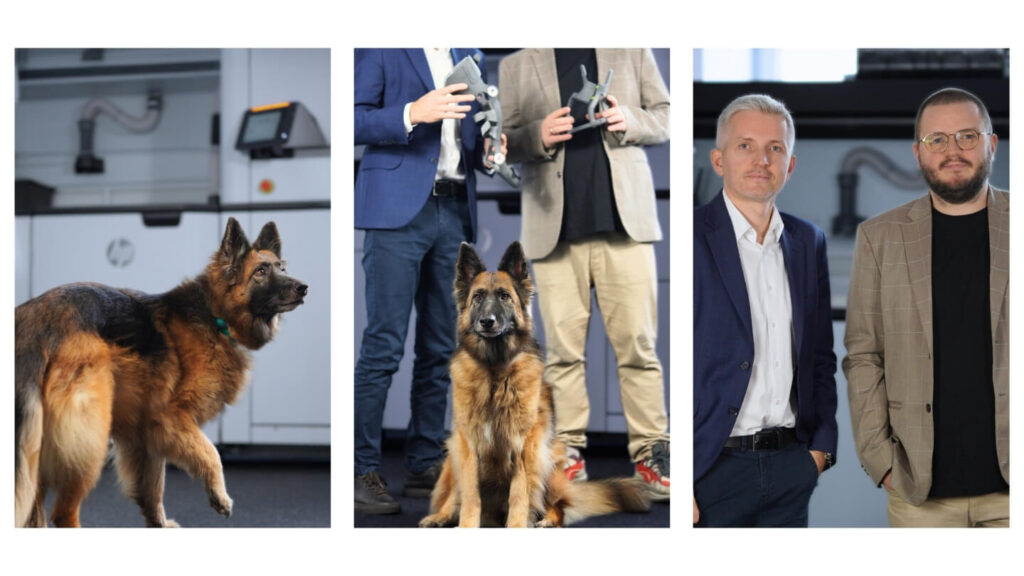

WIMBA, a provider of custom-fit, ultra-light 3D-printed pet orthotics, has announced the opening of its brand-new 3D printing facility at its headquarters in Kraków, Poland. This strategic investment is a significant milestone in WIMBA’s mission to deliver tailored mobility care for pets worldwide. By bringing production in-house, WIMBA aims to set a new standard for quality and efficiency in pet orthotics, ensuring faster delivery and better outcomes for pets, ultimately enhancing their quality of life.

Revolutionizing Pet Care with Quality Control and Faster Production

In-house production allows WIMBA to maintain strict quality control throughout the entire process, ensuring each product meets precise standards for quality and durability.

“With full control over the manufacturing process, we are able to uphold the highest standards for every orthotic and prosthetic, giving pets the best possible care,” added Greg Kosch, CEO and Co-Founder of WIMBA. “Our new facility speeds up production significantly, reducing waiting times for pets that need immediate support. With in-house production processes—including printing, cooling, and sandblasting—we’re able to deliver most standard orthotics within just 10 working days. From the moment the order is placed via WimbaAPP to the moment it reaches the clinic. It also enables us to keep innovating—exploring new materials and refining our designs to better serve pets and veterinary professionals worldwide.

Setting a New Benchmark for Pet Orthotics and Prosthetics

The new facility enables WIMBA to accelerate the production process, ensuring quicker turnaround times for custom orthotics and dog prosthetics. By taking control of the entire production line, WIMBA ensures that each product is crafted with precision to meet the unique needs of every pet.

“Opening our own printing facility marks a new chapter in our journey to becoming the global leader in pet orthotic and prosthetic solutions,” said Franek Kosch, COO and Co-Founder of WIMBA. “This development elevates our ability to deliver superior quality products and underscores our commitment to industry-leading innovation.”

Pet Tech and Vet Tech Market is Booming

The global pet market is $235 billion and is predicted to reach $360 billion in 2030 (source: Fortune Business Insights) making it three times the size of the children’s market. Veterinary orthopedics itself is a nearly $20 billion market. Up to 40% of dogs and 25% of cats require orthopedic care. There are about 600 million dogs and an equal number of cats in developed countries alone. What’s more, factors such as changing demographics, rising incomes, and the COVID-19 pandemic have led to increased pet adoption, with owners viewing their pets as true family members, contributing to rising spending among this group.

***

About WIMBA

Founded in 2022, WIMBA is addressing the growing demand for pet orthotics with its innovative solutions. Despite being a young startup, WIMBA has already partnered with over 220 veterinary professionals across 25 countries, helping more than 700 pets regain mobility. As pet ownership grows and pet owners increasingly see pets as family, WIMBA is positioned to lead the way in modern, personalized orthopedic care, ensuring pets everywhere receive the support they deserve.